Written by:

Aleks Nemtcev

Updated:

February 26, 2024

Noblie / Blog / D2 steel: A Comprehensive Guide for Knife Enthusiasts

Contents [hide]

- 1 Chemical Composition of D2 steel

- 2 Physical and Mechanical Properties of D2 steel

- 3 Heat Treatment of D2 steel

- 4 Applications in Knife Making

- 5 Working with D2 Steel

- 6 D2 Steel Compared to Other Knife Steels

- 7 D2 Steel vs. Stainless Steel

- 8 D2 Steel vs. Carbon Steel

- 9 D2 vs. 1095

- 10 D2 Steel vs. S30V

- 11 D2 vs. 8Cr13MoV

- 12 AUS-8 vs. D2

- 13 A2 vs. D2 Tool Steel

- 14 14C28N vs. D2

- 15 154CM Steel vs. D2

- 16 K110 vs. D2

- 17 Care and Maintenance of D2 Steel Blades

- 18 Handling and Use

- 19 Conclusion

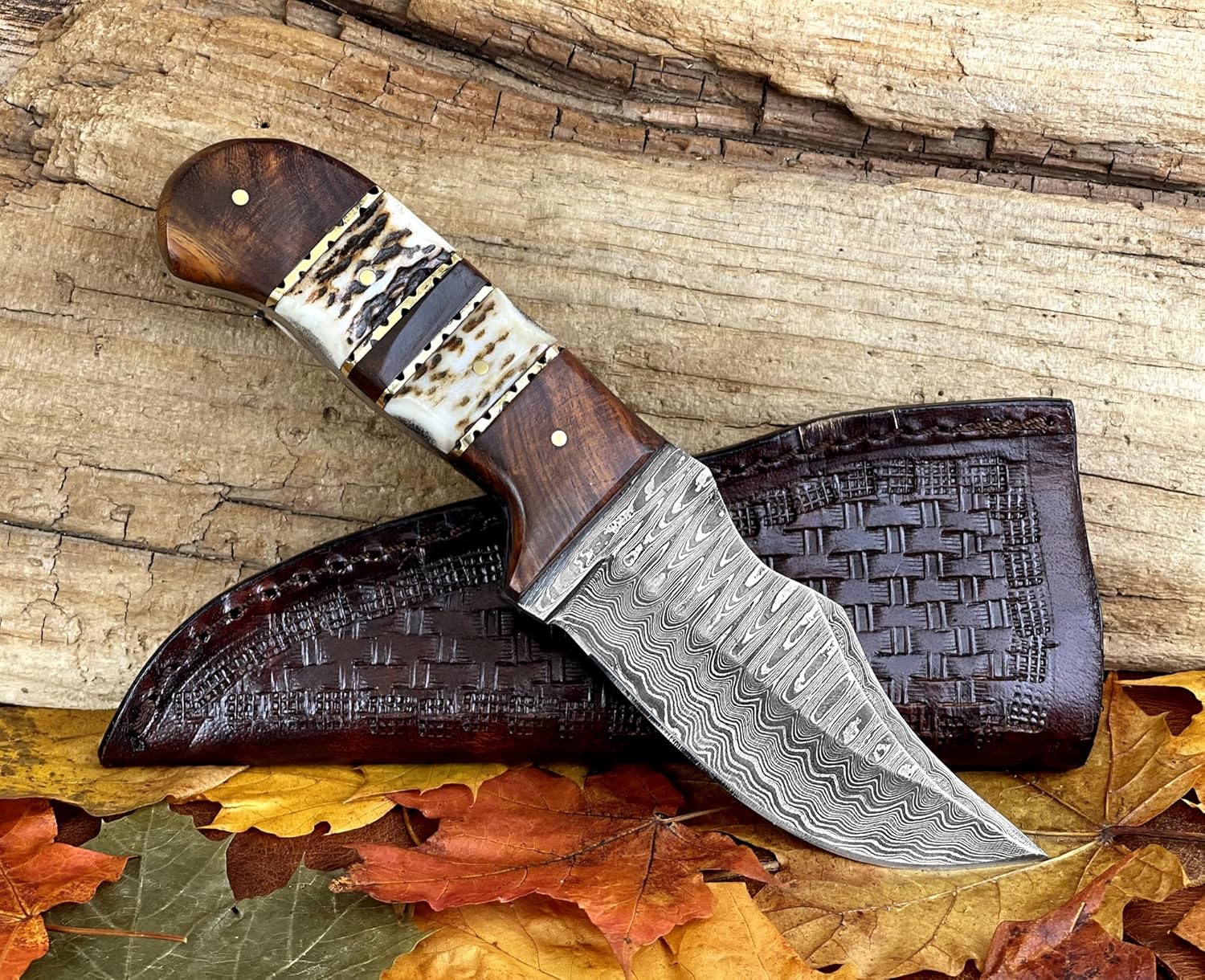

In the realm of tool making, particularly in the crafting of high-end knives, D2 steel stands out as a material of choice for artisans and manufacturers alike. Known for its impressive blend of wear resistance, hardness, and the ability to hold a fine edge, D2 tool steel represents a significant advancement in metallurgical engineering. D2, also known by other names such as SKD11 (Japanese designation), 1.2379 (German designation), Hitachi SLD, and Uddeholm Sverker 21, is a common tool steel and knife steel, has carved a niche for itself in the knife-making world.

This air-hardening, high-carbon, high-chromium tool steel is renowned for its ability to withstand abrasive wear better than other types of carbon steels. This characteristic alone makes it a prime candidate for knife blades that require longevity and durability in cutting performance. Beyond its hardness, D2 steel is celebrated for its advantages, including a moderate level of corrosion resistance and the ability to achieve a razor-sharp edge through meticulous sharpening practices. These attributes combine to offer a material that is both practical and sought after by enthusiasts and professionals.

[affegg id=12]

Chemical Composition of D2 steel

The chemical composition of D2 steel is a finely tuned balance of elements that contribute to its standout properties in tool making. At its core, D2 steel is distinguished by a high carbon content, typically ranging between 1.4% to 1.6%, which is pivotal in achieving its renowned hardness and wear resistance. The presence of 11% to 13% chromium not only enhances its corrosion resistance but also plays a critical role in the steel’s hardenability and strength. The high chromium content, while not enough to classify D2 as a stainless steel, provides a significant level of protection against corrosion, making it more resilient in various environments compared to other high-carbon steels. Additionally, D2 steel contains molybdenum (up to 0.8%) and vanadium (up to 1%), two elements that further improve the material’s toughness and ability to hold a sharp edge over prolonged periods of use. Small quantities of manganese and silicon are also found in its composition, aiding in the steel’s overall durability and resistance to abrasion.

Physical and Mechanical Properties of D2 steel

[affegg id=12]

The physical and mechanical properties of D2 steel underscore its reputation as a premier choice for high-end tool manufacturing, particularly in the knife industry. One of the most heralded D2 steel properties is its exceptional hardness, typically reaching 57-62 HRC (Rockwell Hardness Scale) when properly heat-treated. This level of hardness ensures that tools and knives crafted from D2 steel can endure heavy use and maintain a sharp edge longer than those made from softer materials. However, it’s the steel’s toughness—a measure of its ability to absorb energy and resist cracking under stress—that truly sets it apart. Despite its high hardness, D2 maintains a good level of toughness, thanks to its high chromium and carbon content, making it less prone to chipping and breaking.

In addition to its hardness and toughness, D2 steel exhibits commendable corrosion resistance, though it is not entirely stainless. The chromium content, which is above 11%, offers a protective layer against oxidation and rust, especially in dry environments or with proper maintenance. However, it should be noted that while D2 steel is more resistant to corrosion than many other high-carbon steels, it may require more care and maintenance to prevent rust compared to true stainless steels.

HEAT TREATMENT OF D2 STEEL

The heat treatment of D2 steel is a critical process that significantly enhances its mechanical properties, optimizing it for a wide range of applications, especially in tool and knife making. The D2 steel heat treatment process involves a series of carefully controlled steps, including preheating, austenitizing, quenching, and tempering, designed to maximize the material’s hardness, toughness, and wear resistance. Initially, D2 steel is preheated to prepare the material for austenitizing, where it is heated to a temperature between 980°C to 1050°C (1253K to 1323K). This step is crucial for dissolving carbides in the steel and creating a uniform austenitic structure.

Following austenitization, the steel is rapidly cooled or quenched, typically in air or a controlled atmosphere, to achieve a martensitic structure. This rapid cooling is what imparts the steel’s high hardness. However, at this stage, the steel is exceedingly hard and somewhat brittle, necessitating a tempering process. During tempering, the steel is reheated to a lower temperature, usually between 150°C to 650°C (423K to 923K), depending on the desired balance of hardness and toughness. This step relieves stresses induced by quenching and adjusts the hardness to a more practical level while improving toughness.

[affegg id=12]

Applications in Knife Making

D2 steel has emerged as a preferred material in the art and science of knife making, celebrated for its remarkable blend of durability, edge retention, and resistance to wear. This has led to a significant presence of D2 steel knives in the market, ranging from everyday carry (EDC) knives to specialized cutting tools used in various industries. The choice of D2 steel in knife making is not coincidental but a calculated decision based on its superior properties that meet the rigorous demands of both craftsmen and users.

The process of D2 steel knife making involves leveraging the steel’s high carbon and chromium content, which not only provides the hardness necessary for a lasting edge but also offers a degree of corrosion resistance uncommon in high-carbon steels. This unique combination makes D2 steel knives exceptionally well-suited for tasks requiring precision cutting over extended periods, without the frequent need for resharpening. Moreover, the steel’s toughness ensures that these knives can withstand the pressures and impacts of heavy-duty use without succumbing to chipping or breaking.

What makes the best D2 steel knives stand out is not just the material’s inherent qualities but also the craftsmanship involved in their creation. Top-tier D2 knives are the result of meticulous heat treatment processes that optimize the steel’s physical properties to suit specific uses. Whether it’s a chef’s knife demanding unparalleled sharpness and edge stability or a tactical knife requiring toughness and wear resistance, the best D2 steel knives are tailored to exceed performance expectations.

WORKING WITH D2 STEEL

Working with D2 steel presents unique challenges and opportunities due to its distinctive properties, especially when it comes to machinability and weldability. Known for its high wear resistance and hardness, D2 steel requires careful handling and specialized techniques to shape and join effectively. Understanding the nuances of working with D2 steel is crucial for craftsmen and manufacturers aiming to harness its full potential in creating high-quality tools and components.

Machinability of D2 steel, while not as straightforward as with more malleable materials, can be effectively managed with the right approach. Due to its hardness, machining D2 steel often necessitates the use of robust, carbide-tipped tools to prevent wear and ensure precision in cutting operations. Operating at lower speeds and using a coolant can also mitigate the risk of overheating, which can alter the steel’s properties and lead to premature tool failure. Pre-heat treating the steel to soften it slightly can further enhance machinability, allowing for easier shaping before final hardening and tempering processes are applied. While pre-heat treating can improve machinability, it’s important to note that this alters the final properties of the steel and should only be done if the final hardened and tempered properties are not crucial for the application.

When it comes to welding, D2 steel poses certain challenges due to its high chromium content and susceptibility to cracking under thermal stress. However, with appropriate D2 steel welding techniques, successful welding is achievable. Preheating the steel to a specific temperature range before welding can help minimize thermal shock and reduce the risk of cracking. Employing a low-hydrogen welding rod and maintaining a controlled welding speed and temperature is also crucial to prevent the introduction of additional stresses. Post-weld heat treatment is often recommended to relieve any residual stresses and restore the desired properties in the weld zone and heat-affected areas.

[affegg id=10]

D2 STEEL COMPARED TO OTHER KNIFE STEELS

In the world of knife making, the selection of steel is crucial, as it directly influences the knife’s performance, durability, and maintenance requirements. D2 steel, known for its high wear resistance and toughness, is often juxtaposed with other popular knife materials, such as stainless steel and carbon steel. This comparison sheds light on the unique characteristics of D2 steel and how it stacks up against these traditional choices, aiding knife makers and users in making informed decisions based on the intended use of the knife.

D2 STEEL VS. STAINLESS STEEL

D2 steel, characterized as semi-stainless due to its high chromium content (11% to 13%), strikes a balance between the corrosion resistance offered by traditional carbon steels and true stainless steels. Compared to most stainless steels, which typically contain over 13% chromium—such as 440C or 304 stainless steel—and offer even greater corrosion resistance, D2’s slightly lower chromium level means it might succumb to rust under specific conditions. However, this very characteristic of D2 steel enhances its edge retention and wear resistance, outperforming many stainless steels in these aspects. Stainless steel knives, renowned for their minimal maintenance needs and robust resistance to rust, are ideally suited for culinary purposes or use in moist environments. On the contrary, D2 steel knives, with their exceptional hardness and prolonged edge sharpness, are better equipped for intensive cutting tasks where the primary concerns are durability and the willingness of the user to engage in regular upkeep.

D2 STEEL VS. CARBON STEEL

Carbon steel is celebrated for its sharpness and simplicity in sharpening. D2 steel, enriched with high carbon and chromium levels, offers an admirable synthesis of hardness and toughness. This composition renders it more resilient to wear and abrasion than the majority of carbon steels. While carbon steel knives are unmatched in sharpness and straightforward maintenance, they demand vigilant care to avert rust and corrosion. D2 steel, conversely, presents a superior resistance to corrosion, thanks to its chromium content, although it does not reach the levels of stainless steels. It also maintains a sharp edge for more extended periods under rigorous usage conditions. The choice between D2 and carbon steel frequently hinges on the user’s preferences: the peerless sharpness and sharpening ease of carbon steel versus the durable, enduring edge and moderately improved corrosion resistance of D2 steel.

| Steel | Wear Resistance | Edge Retention | Corrosion Resistance | Toughness | Sharpening Difficulty |

| D2 | High | High | Moderate | High | Hard |

| 1095 | Medium | Medium | Low | High | Easy |

| S30V | High | Very High | High | Medium-High | Medium |

| 8Cr13MoV | Medium | Medium | High | Medium | Easy |

| AUS-8 | Medium | Medium | High | Medium | Easy |

| A2 | High | High | Moderate | Very High | Medium |

| 14C28N | Medium-High | High | Very High | Medium | Easy |

| 154CM | High | High | High | Medium | Medium |

| K110 | High | High | Moderate | High | Hard |

D2 VS. 1095

D2 and 1095 steel contrast significantly in their composition and performance characteristics. D2 is a semi-stainless tool steel with high chromium content, offering good wear resistance and moderate corrosion resistance. It’s known for its toughness and ability to hold an edge. On the other hand, 1095 is a high-carbon steel with very low chromium, making it highly prone to rust if not properly cared for. However, 1095 is easier to sharpen and can achieve a very fine edge, making it popular for knives that require a razor-sharp blade, such as kitchen knives and outdoor tools.

D2 STEEL VS. S30V

D2 and S30V are both high-end steels used in premium knives. S30V, developed specifically for knife making, offers an excellent balance of edge retention, corrosion resistance, and toughness, thanks to its fine carbide distribution achieved through the Crucible Particle Metallurgy (CPM) process. D2, while offering excellent wear resistance and toughness, falls short of S30V in terms of corrosion resistance and is a bit more challenging to sharpen due to its higher wear resistance.

D2 VS. 8CR13MOV

D2 and 8Cr13MoV cater to different segments of the knife market. D2, with its high wear resistance and toughness, is considered a higher-end tool steel. In contrast, 8Cr13MoV is a budget-friendly stainless steel that offers decent edge retention, ease of sharpening, and good corrosion resistance. Knives made from 8Cr13MoV are generally more affordable but won’t perform as well in terms of edge retention and durability compared to those made from D2.

AUS-8 VS. D2

AUS-8 and D2 steels are quite different in their performance and use cases. AUS-8, a Japanese stainless steel, offers good corrosion resistance, ease of sharpening, and decent toughness but lacks in wear resistance when compared to D2. D2’s higher carbon and chromium content provide it with superior edge retention and wear resistance, making it suitable for heavy-duty applications. However, D2’s semi-stainless nature means it’s more susceptible to corrosion than AUS-8.

A2 VS. D2 TOOL STEEL

A2 and D2 tool steels are both part of the cold work tool steel category, known for their durability and resistance to deformation under stress. A2 offers excellent toughness and good wear resistance with better corrosion resistance than D2 due to its slightly higher chromium content. D2, on the other hand, provides superior wear resistance and edge retention but is less tough, making it more prone to chipping in certain applications. Both steels require careful maintenance to prevent corrosion, with D2 being slightly more demanding due to its semi-stainless nature.

14C28N VS. D2

14C28N, developed by Sandvik in Sweden, is a stainless steel designed for excellent edge performance, corrosion resistance, and high hardness. It’s often used in kitchen knives and outdoor tools for its ability to maintain a sharp edge and resist rust. D2, with its higher carbon and chromium content, surpasses 14C28N in wear resistance and edge retention but doesn’t match the corrosion resistance offered by 14C28N. 14C28N is generally easier to sharpen than D2 and is preferred in applications where frequent exposure to moisture or corrosive substances is expected.

154CM STEEL VS. D2

154CM is a high-carbon, high-chromium stainless steel known for its superior corrosion resistance, good toughness, and excellent edge retention. It’s considered an upgrade from the basic 440C stainless steel, offering improved performance in premium knives. D2, while providing exceptional wear resistance and toughness, falls slightly behind 154CM in corrosion resistance and ease of sharpening. Both steels are popular among knife enthusiasts for their durability and ability to maintain a sharp edge over extended use.

K110 VS. D2

K110 is Bohler’s equivalent of D2 tool steel, offering very similar properties, including high wear resistance, good toughness, and moderate corrosion resistance. The primary differences between K110 and D2 may arise from the specific manufacturing processes and quality control standards employed by Bohler, potentially offering slight variations in performance. However, for all practical purposes, K110 and D2 can be considered interchangeable in terms of their application in knife making.

CARE AND MAINTENANCE OF D2 STEEL BLADES

Ensuring the longevity and performance of D2 steel knives hinges on adopting a rigorous regimen of care and maintenance. D2 steel, known for its high wear resistance and toughness, also presents a unique set of maintenance challenges due to its semi-stainless nature. Proper D2 steel blade care is paramount for knife owners to maximize their tool’s lifespan and maintain its exceptional performance.

Routine Cleaning

Regular cleaning is a cornerstone of D2 steel blade maintenance. After each use, it’s crucial to wipe the blade clean with a damp cloth to remove any debris or acidic substances that can corrode the steel. For a more thorough cleaning, wash the blade with warm, soapy water, rinse well, and dry immediately to prevent moisture from lingering on the steel, which can lead to rust.

Proper Storage

Storing D2 steel knives in a dry, ventilated area is vital to prevent moisture accumulation that can cause rust. For those residing in humid climates, consider using a dehumidifier or storing your knife with silica gel packets to absorb excess moisture. Additionally, using a knife block or sheath can protect the blade from environmental elements while preventing accidental damage.

Rust Prevention

Although D2 steel has a high chromium content that offers some corrosion resistance, it’s not entirely stainless. To combat potential rusting, apply a light coat of oil to the blade after cleaning and drying. Mineral oil or specialized knife maintenance oils work well for this purpose, forming a protective barrier against moisture.

Sharpening

Maintaining a sharp edge is critical for the optimal performance of any knife, particularly those crafted from D2 steel, known for its hard-wearing properties. Utilize a high-quality sharpening stone or tool designed for hard steels. Sharpening intervals depend on usage but keeping the blade honed will ensure it’s always ready for the next task.

Regular Inspections

Frequent inspections can catch early signs of wear or corrosion, allowing for prompt intervention. Look for any unusual discoloration, spots, or dullness along the edge. Early detection of these issues means easier maintenance and extends the knife’s effective life.

HANDLING AND USE

Practicing proper handling and use is essential for any knife but especially for those made from D2 steel. Avoid using the knife as a pry bar or screwdriver, as misuse can lead to damage to the blade or handle. Cutting on appropriate surfaces, such as wooden or plastic cutting boards, will also help maintain the blade’s sharpness.

Conclusion

The exploration of D2 steel in comparison to stainless steel and carbon steel reveals its distinctive position within the realm of knife-making materials. D2 steel stands out for its semi-stainless nature, balancing the corrosion resistance of stainless steel with the edge retention and toughness closer to that of high-carbon steels. This unique combination of attributes makes D2 steel an excellent choice for a wide range of applications, from heavy-duty cutting tasks to specialized tools requiring durability and prolonged sharpness.

The care and maintenance of D2 steel, while requiring attention to detail, are straightforward and ensure that tools made from this material maintain their integrity and performance over time. Proper cleaning, storage, and regular maintenance such as oiling and sharpening not only extend the lifespan of D2 steel tools but also ensure that they continue to perform optimally.

Leave a Reply